- Learn

- Shop

- -About Staples

- Partner with Us

- Login

When it comes to sustainable innovation we don’t just help our customers become greener, we constantly evolve the way we work to reduce our impact on the environment. This is why we invested £50 million in a new UK super-warehouse, something our lead engineer Steve Smith explains was the smart choice.

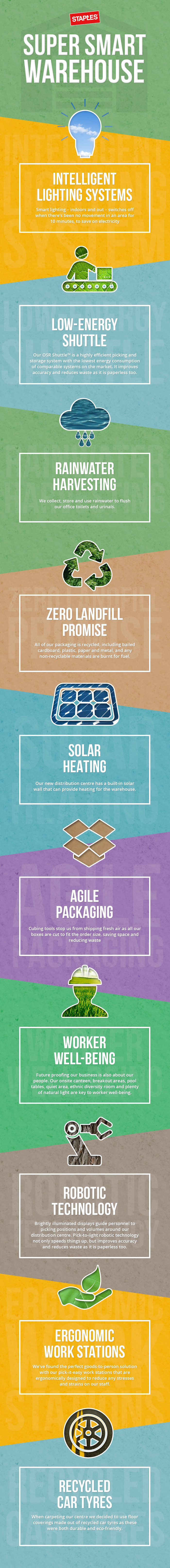

With a solar wall for heating water, intelligent lighting systems saving on electricity and rainwater harvesting systems to flush office toilets and urinals, there’s no doubt that our new distribution site in Corby is making a real difference.

But the past two years has not just been about finding a state-of-the-art facility with enough space and opportunity for our UK operation to grow, or a site constructed from sustainable materials and built on strong environmental principals. This has also been a chance to overhaul our existing systems, and invest in brand new technology to create a work environment of the future.

Robust planning, and investment in the right equipment, has meant we today operate a zero landfill promise at Mitchell Road, all our packaging is recycled (bailed cardboard, plastic, paper and metal) and any non-recyclable material is burnt for fuel.

We save on transport, packaging and waste with our cubing tool that stops us from shipping ‘fresh air’, as boxes are cut to the most appropriate size for each individual order. Where orders are smaller than our smallest box, we ship by envelope. If it is larger, then we devise a bespoke shipment and packaging method.

Everything is system driven and we run an error free model – through logs and weight stations that mean we quite literally can’t make a mistake, which reduces repeat orders and returns, while keeping our customers happy.

Efficiency and well-being are two cornerstones of our new operation. Our former warehouses, for want of a better expression, were dark and dingy and no longer fit the company vision in terms of what we wanted to offer our customers – faster delivery, and a larger selection – how we wanted our business to operate, and what our staff deserved. Mitchell Road in Corby is allowing us to be more streamlined, efficient and sustainable while giving our people a more modern, ergonomic work space to operate in.

We have a fully-functioning canteen serving hot food from 7am until 6pm, breakout areas, a pool table, television, quiet room, ethnic diversity space and natural light – lots of it.

The approach to sustainability at Staples has always been about development. Offering customers the chance to buy eco-preferable products, or save CO2 emissions and reduce packaging is all very well – but we are also focussed on delivering economic and social benefits to our stakeholders.

In terms of our warehousing, this is how we can future proof our operations, invest in our people and choose the most efficient systems that will stand the test of time. It is much more than finding an attractive light and airy building.

For our UK distributions the challenge was to find a site that would enable us to bring together three existing warehouses – located across Birmingham and Corby – in one place, grow, and fulfil our CSR objectives.

It was also a major test to align our systems, as for the first time we are about to bring together the two distinct halves of our business: Staples (consumer facing) and Staples Advantage (business facing).

Along with a team of specialists from across Europe we devised a blueprint, with projections for what was needed at the new location from the number of pallets, to space for our product lines. From here we set out to find the perfect site, and it soon became apparent we needed an existing building that was ready to move into.

We went through a fair bit of pain as we had to make the space fit our needs. Mitchell Road was a speculative build, constructed on a former tip and scrap yard. It was positioned perfectly in the catchment area for our staff both in Birmingham and Corby, with easy access to the motorway system and strong green credentials.

But it was exceptionally challenging to find somewhere that could achieve everything and most of the initial stages were spent reviewing the fit-out from loading bays and racking to shuttle technology and work stations. Whether comparing specs on conveyors or automation we considered longevity – how long it will last, and how economical it will be to repair. It was all about durability and building a road map for all our various systems so we know at any one time exactly when maintenance, upgrades and replacements are needed.

Key to all of this has been looking at our assortment and how we can best fulfil customers’ orders, faster. We went to five different vendors for an overview on how each operated, the advantages and disadvantages, and their products’ USPs.

We ensured our partners had similar values. When road mapping, for example, we didn’t just install the most affordable or attractive conveyor belt – we researched its efficiency, how it had performed in the past, how it could be developed and updated in the future, considered capacity and how we wanted to grow and how we could extend and evolve automation without interfering with current operations.

We re-located Birmingham as part of Phase 1 in October, and the past few months have been about resolving all the natural teething problems you’d expect when working on such a scale. The focus has been on the customer and minimising disruption.

Since the start of the year we have started looking more closely at the business’ KPIs, such as pick rates or working habits. We are now getting ready for phase 2, moving the old Corby site across into the new building.

We have been operating in two-thirds of the warehouse, and plan to take over the rest of the building in 2017/18. We are working with our partners to see how we can better what we are currently doing, whether we can lessen the impact on the environment or improve the working environment for our employees – we are always striving for better ways to do things.

Our priorities now are keeping up on industry news, researching new ways of thinking and innovative new practices, visiting sites and learning from peers. One of our key takeaways from phase 1 is that it’s vital we invest as much time as we can in this initial stage, doing our homework, and looking at every detail so we make sure it all adds up.

This time we have had to make our needs fit an existing building but it would be very different if we were starting from scratch. If we had built from new we’d have wanted even greener tech such as renewables (wind turbines, or full solar panelling to power the entire building) – with the chance to sell back excess energy to the national grid, or maybe even power some local community facilities.

When it comes to sustainability, we like to see ourselves as industry trailblazers and have ambitious year-on-year targets to recycle more and reduce waste, cut carbon emissions and scale back electricity use, through a number of aspirational campaigns. It’s why we have more than 12,000 eco-conscious products on the market for our customers, and are always looking at ways to practice what we preach.

You can call a Staples representative at the following number:

+353 (0) 1 553 0078

You can also fill out the form below and one of our representatives will get in touch with you shortly